Railway sleeper concrete batching plant(RDSO Approved with STR)

A facility where railway sleepers are manufactured. They undergo rigorous testing by Indian railways before they are incepted for use. Here all test reports and data is to be logged into a computer , the process is known as STR. This process is made compulsory for all sleeper manufacturing facilities across india.

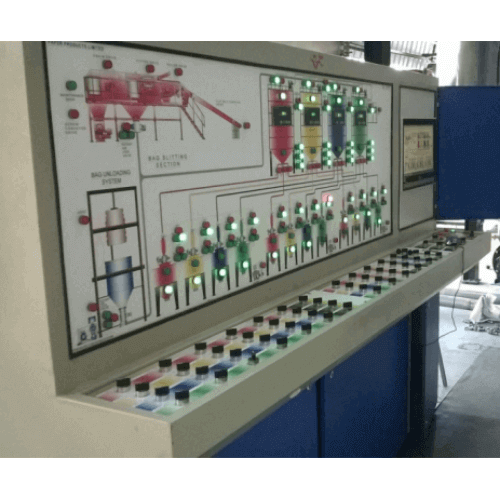

Batching Systems And Plant Automation

Concrete Batching FULLY AUTO

The process of mixing raw material namely 20mm grit, 10 mm grit, sand, cement , water and admixture according to the recipe predefined according to the desired strength and atmospheric conditions is carried out by this system in semi auto and fully auto mode.

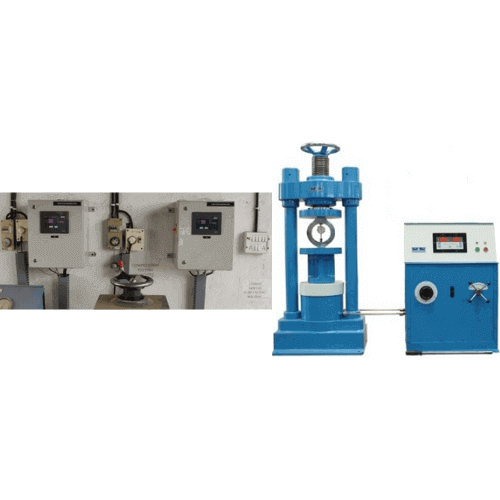

Cube Testing, Beam Testing & SBT

After the sleeper is cast strength testing is done by this apparatus, with the help of our control panel

Tensioning

After the sleeper is cast strength testing is done by this apparatus, with the help of our control panel

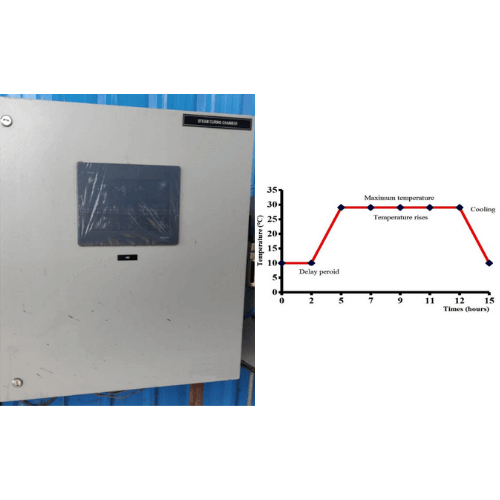

Steam Cycle control system

the sleeper undergoes a 12 hour steam cycle before curing controlled by this panel

Vibrator RPM

This panel is responsible for controlling the vibrators below the casting bench for a pre defined time at about 9000 rpm while casting the sleeper. It helps the concrete to settle without forming an air bubble.

Plant automation

We also provide plant automation solution designated for a customized product starting from processing raw material to packing a finished product. Moreover process automation facilities are also provided for existing plant.

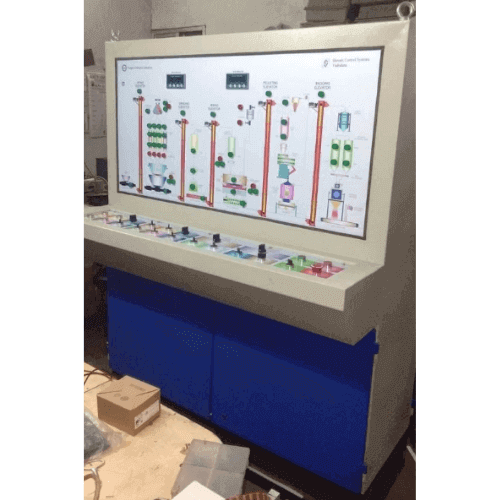

Process automation

This system is responsible to control all the machineries in a plant, sequential start and Material management according to supply and demand. This system completely eliminates human errors

Poultry, cattle and fish feed plant automation(plc/ scada) with batching

this system controls the plant from creating a batch of raw materials according to recipe, grinding the batch, mixing molasses and chemicals at controlled temperature for a fix duration of time , processing the material through the pellet mill and passing the finished product to the storage bins after cooling it . the process ias controlled by a computer and PLC together